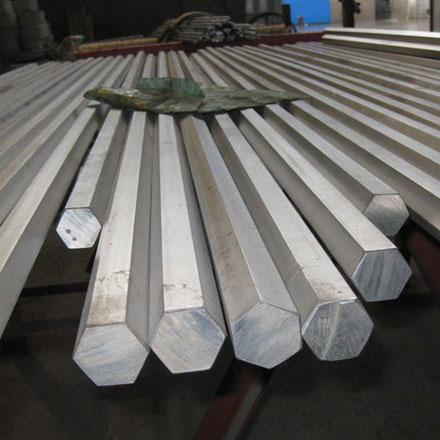

SMO 254 Square Bar, SMO 254 Flat Bar, ASTM A276 SMO 254 Bars, SMO 254 Hex Bar, UNS S31254 Round Bar, SMO 254 Rods, SMO 254 Round Bar, SMO 254 Round Bar Supplier in Mumbai, India.

Veer Impex is dedicated to providing high-quality SMO 254 Round bar. We are trusted and certified wholesalers with a reputation for delivering high-quality goods all around the world. Veer Impex meticulously monitors the whole steel production process while conducting stringent quality checks to ensure that the highest quality products with the greatest lifespan are delivered.

Safety

Quality

Integrity

Largest Inventory

In chemistry stability, silicon, manganese less than 1%, chromium up to 20%, a nickel less than 18%, molybdenum not more than 6%, and copper up to 1% are also included in the chemical composition of SMO 254 round bar for efficient results. Due to a mixture of molybdenum and nitrogen, SMO 254 has a strong capacity to resist ordinary corrosion, crevice and pitting. This grade possesses high mechanical and chemical properties, along with high welding properties. SMO 254 grade offers good resistance properties and is generally considered low-level carbon but has high applicability across chemical equipment due to higher tensile strength. SMO 254 forms its scope for forming and bending applications, recommended cold bending and possesses balanced machinabilities. SMO 254 is supplied heat treated by default. If further processing is required, it can be heated to 1150-1200 degrees Fahrenheit; nevertheless, water quenching is recommended for further industrial applications. SMO 254 type features combat characteristics against bromides and fluorides ions, higher flexibility and preferred alternatively to high-cost Round bars. SMO 254 Round Bar is applicable in chemical processing, oil and gas industries, pharmaceutical equipment, and many others.

SMO 254 Rods, SMO 254 Bright Bar Stockists, ASTM A276 SMO 254 Round Bars, SMO 254 Cold Finish Round Bar, 1.4547 Round Bars, SMO 254 Forged Bar Exporter in India.

ASTM A276 SMO 254 Hexagonal Bars, SMO 254 Polished Bars at Best Price, SMO 254 Threaded Bar, SMO 254 Industrial Bars Distributors, SMO 254 Round Bar Manufacturer in India.

ASTM A276 SMO 254 Round Bars Equivalent Grades

| STANDARD | WERKSTOFF NR. | UNS | EN | SS |

| SMO 254 | 1.4547 | S31254 | X9CrNiSiNCe21-11-2 | 2368 |

SMO 254 Bars Forms in Stock

- ASTM A276 SMO 254 Round Bar

- SMO 254 Round Bar

- UNS S31254 Round Bar

- 1.4547 Round Bars

- SMO 254 Round Bars

- ASTM A276 SMO 254 Square Bar

- SMO 254 Square Bars

- UNS S31254 Square Bar

- 1.4547 Square Bars

- SMO 254 Square Bar

- ASTM A276 SMO 254 Bright Bar

- SMO 254 Bright Bar

- UNS S31254 Bright Bar

- 1.4547 Bright Bars

- SMO 254 Bright Bar

Stock Size Range and Specifications For SMO 254 Round Bar

| Specification : | EN, DIN, JIS, ASTM, BS, ASME, AISI |

| Standard Specification : | ASTM A276, A479 / ASME SA276, SA479 |

| Size : | 15NB to 150NB IN |

| Diameter : | 3.17mm to 350mm diameter |

| Length : | 100 mm to 3000 mm Long & Above |

| Tolerance : | H8, H9, H10, H11, H12, H13K9, K10, K11, K12 or as per clients’ requirements |

| Finish : | Black, Bright Polished, Rough Turned, NO.4 Finish, Matt Finish, BA Finish |

| Form : | Round, Square, Hex (A/F), Rectangle, Billet, Ingot, Forging Etc |

| Surface : | Hot Rolled Pickled or Sand Blasting Finished, Cold Drawn, Bright, Polished, Hairline |

| Condition : | Cold Drawnd Pulished Cold Drawn Centreless Ground & Polished |

Chemical Composition of SMO 254 Round Bars

| Grade | C | Mn | Si | S | N | Cr | Ni |

| SMO 254 | 0.05 - 0.1 | 0.8 min | 1.1 - 2.0 | 0.03 min | 0.14 - 0.2 | 20 - 22 | 10 - 12 |

Mechanical Properties of SMO 254 / S31254 / 1.4547 Round Bars

| Element | Density | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SMO 254 | 7.8 g/cm3 | Psi – 87,000, MPa – 600 | Psi – 45,000, MPa – 310 | 40 % |

Markings On The SMO 254 Round Bar

The full identification of the bars should be continuously marked down its whole length, including :

- Rating Designation

- Material Designation

- "WP" in grade symbol

- Grade

- Schedule number or nominal wall thickness

- Heat Code

- Manufacturer’s Name or Symbol

SMO 254 Bars Application Industries

- Aerospace Industry

- Chemical Industry

- Energy Industry

- Food Processing Industry

- Oil and Gas Industry

- Petrochemical Industry

- Pulp & Paper Indusry

- Pharmaceuticals Industry

- Power Plant Industry

If You Are Looking To Buy High Quality SMO 254

Round, Square, Forged, Hollow Bar With Mill And Third Party Test Certificate.

SMO 254 Round Bar Price List

Request the latest ASTM A276 SMO 254 Bars Price List. Please Call +91 9167014755 / +91 9082006249 or Send an Email to info@veerexport.com for SMO 254 Round Bar Ready stock information and updated price list.