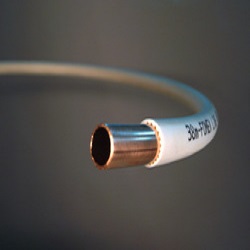

PVC COATED GAS TUBE,PVC COATED GAS PIPE,PLASTIC COATED COPPER TUBE,ARAI APPROVED PVC COATED TUBE,LPG COPPER PIPE,LPG COPPER TUBE,ARAI APPROVED PVC COATED PIPE,PVC COATED COPPER PIPE,PLASTIC COATED COPPER PIPE,PVC COATED COPPER TUBE.

Veer Impex is the reputed manufacturer and supplier of heavy duty Pvc coated copperPipe. We are supplying these pipes in various specifications, standards, designations and custom dimensions. To achieve flawless products, we are undertaking national and international standards while manufacturing the pipes. With our large processing unit and advanced machines, the production of pipes is done with 100% precision.

Pvc coated copperPipe is high carbon alloy steel pipes. This results produced pipe is harder due to the addition of carbon amount. During the formation of pipes carbon addition increase toughness and hardness, however, it reduces strength.

These pipes are used in the conditions where wear, tear and abrasion reductions are the main concerns. These pipes are suitable for piping applications. In construction and fabrication, the grade and composition of pipes used to make a huge impact on the end pipes. The pipes are common boasts as tougher quality and harder four times as standard grades.

These pipes are made by quenching and tempering process. While the manufacturing process, the grain structure is changed to increase the toughness and improve formability that results in hardening of materials.

These pipes have great resistance to crevice and pitting corrosion in terms of adverse environments. The pipes have high temperature stability without any deformation and elongation. These pipes have great elevated strength in stress corrosion cracking environments where the issue is sulfides, chlorine, nitric acids, phosphoric acids, sulfuric acids, chlorides, halides, and more. Also, these pipes are exposed in the process streams. pipes can be applied in the environments where grain boundary precipitation is a concern.

The reheating of pipes break down crystal structure formed in the quenching process. The long lasting cooling allows crystal structure reform and maintaining the strength and hardness but increase overall ductility.

Moreover, the heat treatment and annealing process are performed on the pipes to achieve the desired mechanical strength and ductility. Furthermore, the cold working operations are performed to prevent embrittlement while retaining adequate mechanical dimensions.

The pipes get the desired dimensions and accurate finish after the industrial finishing process. Moreover, these are processed from industrial coats that prevent additional protection from the oxidation.

Safety

Quality

Integrity

Largest Inventory

Quality policy-

We are serving services in the field of industrial piping products for decades of years. Here we adhere to quality standards at all level of production levels. We are doing continuous efforts for improvement of material tech and tools to provide the best quality products. the pipes provided by us are tested and inspected under the norms of international standards.

Different tests performed by us are destructive test/ non-destructive test and material tests.

Destructive tests-

• hydrostatic test

• Charpy test

• Mechanical test

• hardness test

• compression test

• tensile test

• pressure test

• flaring test

• flattening test

Non-destructive tests-

• positive material (PMI) test

• micro / macro test

• chemical test

• intergranular corrosion (IGC) test

• ultrasonic test

• radiographic test

• pitting corrosion test

We also provide some test certificates and quality reports along with products that show or quality. the reports are NABL test report, material test certificates, raw material test report, mill test report, quality assurance plan (QAP), and heat treatment charts.

Other reports are-

• product invoice

• specification guide

• welding guide

• disinfection certificates

• packaging details

We use standard packaging materials to ensure 100% safe delivery of Pvc coated copperPipe. The packaging includes plywood cases, wooden cartons, pallets, and bundles. Moreover, end caps are also used to prevent jerks while exporting.

PVC COATED COPPER PIPE STOCKIST,LPG COPPER TUBE SUPPLIER,LPG COPPER PIPE SUPPLIER,ARAI APPROVED PVC COATED TUBE SUPPLIER,PVC COATED COPPER PIPE MANUFACTURER,ARAI APPROVED PVC COATED PIPE STOCKIST,PLASTIC COATED COPPER TUBE SUPPLIER,PVC COATED GAS TUBE MANUFACTURER.

ARAI APPROVED PVC COATED TUBE STOCKIST,PVC COATED GAS PIPE SUPPLIER,ARAI APPROVED PVC COATED PIPE MANUFACTURER,LPG COPPER TUBE STOCKIST.

Carbon Steel Pvc coated copperPipe Forms in Stock

Stock Size Range and Specifications For Pvc coated copperPipe

| Range : | 1mm to 25mm / as per customer required |

| Thickness : | 0.5mm. 1mm, 1.5mm, 2mm (PVC thick) |

| Color : | Custom Color Available |

| Length : | Custom Cut Lengths. |

Markings On The Pvc coated copperPipes

The full identification of the pipe should be continuously marked down its whole length, including :

- Nominal Pipe Size (Nominal Bore)

- Schedule (Wall Thickness)

- Specification

- Grade

- Method of Manufacturer (Seamless)

- Heat Number

- Manufacturer’s Name or Symbol

Application Industries

- Aerospace Industry

- Chemical Industry

- Energy Industry

- Food Processing Industry

- Oil and Gas Industry

- Petrochemical Industry

- Pulp & Paper Indusry

- Pharmaceuticals Industry

- Power Plant Industry

People Also Searched for

PVC COATED COPPER TUBE MANUFACTURER,PVC COATED COPPER PIPE SUPPLIER,PVC COATED GAS PIPE MANUFACTURER,ARAI APPROVED PVC COATED TUBE MANUFACTURER,LPG COPPER TUBE MANUFACTURER,PLASTIC COATED COPPER PIPE STOCKIST,PLASTIC COATED COPPER PIPE SUPPLIER,PVC COATED COPPER TUBE STOCKIST,ARAI APPROVED PVC COATED PIPE SUPPLIER,PVC COATED GAS TUBE SUPPLIER,PVC COATED GAS PIPE STOCKIST,PVC COATED COPPER TUBE SUPPLIER,LPG COPPER PIPE STOCKIST,PLASTIC COATED COPPER TUBE MANUFACTURER,PVC COATED GAS TUBE STOCKIST,PLASTIC COATED COPPER PIPE MANUFACTURER,LPG COPPER PIPE MANUFACTURER,PLASTIC COATED COPPER TUBE STOCKIST.

If You Are Looking To Buy High Quality

Seamless, Welded, ERW, EFW, SAW, LSAW, DSAW Pipe With Mill And Third Party Test Certificate.

.jpg)

Pvc coated copperPipes Price List

Request the latest Pvc coated copperPipes Price List. Please Call +91 9167014755 / +91 9082006249 or Send an Email to info@veerexport.com for Pvc coated copper Pipes Ready stock information and updated price list.